By Gwen Spicer, conservator in private practice, and Yadin Larochette, Tru Vue museum and conservation liaison

This article was first published in AIC News, Vol. 46(2), March 2021, pp. 34-36. It is reprinted here with permission.

What are Magnetic Cleaning Devices?

We first heard about the application of magnetic cleaning devices for cleaning display cases in an article on glass fogging (Poulin et al. 2019). Magnetic cleaning devices contain two components, allowing for both sides of acrylic or glass glazing to be cleaned simultaneously via access to only one side, as the magnets pull their partner cleaning pad along the glass. These tools could help clean display cases, especially in hard-to-reach areas.

We presented an overview of these devices at the Mountmaker’s Forum 2020, which can be viewed here.

A Brief History

The use of magnets to clean windows is not a new idea. A 1920 patent describes a system using electro-magnets. Today Alnico and neodymium magnets are used in these cleaners. Alnico magnets composed of iron alloy with aluminum, nickel, and cobalt were first developed in the 1930s. Later, in the last quarter of the 20th century, neodymium, a rare earth element, revolutionized the field of magnetic materials due to its much higher maximum energy product (strength) and coercivity (resistance to changes in magnetization). However, recent supply challenges and neodymium’s poor temperature and corrosion resistance have left room for renewed attention and advances in Alnico technology, such as the addition of boron, imparting improved strength and coercivity (Spicer 2019). It’s important to know which type of magnet is present within a cleaning apparatus in order to store it properly. Neodymium magnets can damage electronic devices (such as cell phones) and will demagnetize Alnico magnets, including recently improved grades.

Current Use

The success of these tools depends upon matching a magnet’s strength with the thickness of the glazing. Two kinds of magnetic cleaning devices are readily available: One designed for aquariums and one for windows. Prices range anywhere from $7 to $125, depending on the size of the device and if the magnet’s position is adjustable. Some window cleaners have rotating knobs that move the magnets closer to or further away from the device surface, which in turn strengthens or weakens the magnet pull force. Adjustable devices seem to be exclusively designed for windows and not for aquariums.

Polar Orientation and Why It Matters

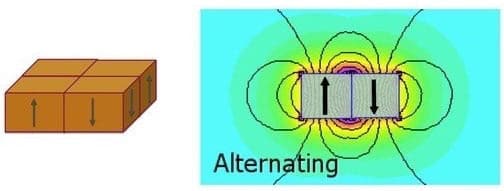

Some of the devices with the weaker Alnico magnets (as opposed to neodymium) capitalize on alternating their polar orientation for increased strength. When a group or series of magnets is positioned with alternating polar directions such that one is south-facing when the neighbor is north-facing, the strength of the entire group will be increased evenly on both sides (see Figure 1a). In this way the group of magnets acts as one larger magnet with unified flux lines (see Figure 1b).

Devices Designed for Windows

Devices for windows are available in all sorts of sizes and shapes and usually include a security rope on the part used on the window exterior. Window cleaners tend to include blades, like those found on windshield wipers or squeegees. These blades are great for moving liquid across the glazing surface but are not necessary for within a museum setting. In order to accommodate space for these blades to move back and forth and for liquid to move freely, there are small bumps on the magnet housing that raise the device away from the glazing surface. These small, raised areas create uneven pressure against the glazing.

Devices Designed for Aquariums

Devices designed for aquariums, on the other hand, do not contain blades and have an overall even surface. This allows for consistent contact with the glazing and no pressure points.

The surfaces of each of the two components of the device are different:

- One surface is designed to scrape algae off an aquarium’s interior. Its texture is similar to the hook side of hook and loop fasteners, like Velcro.

- The surface of the matching component designed for the aquarium’s exterior is much softer and fuzzy in texture, similar to velvet.

To avoid scratching the glass or acrylic, cleaning cloths need to be placed over the surface of each component.

Aquarium cleaners, like the window cleaners, are available in a variety of sizes, and each size is designed for different glazing thicknesses. If we look at one brand for the sake of comparison (we are not recommending this brand over any other), a small size is designed for 5mm thickness, a medium for 10mm thickness, and a large for 16mm thickness (see Figure 2).

Which Would be Best for Cleaning Display Cases?

Based on our experiments, we like the aquarium cleaners over the window cleaners when used in conjunction with microfiber cloths. We’ve been doing tests with two types of 100% polyester cloths; one with an ultra-suede type texture, and another very plush loop weave. The varying thicknesses of the two cloths allow for adjusting the strength of the magnetic pull force: The thicker the cloth, the larger the distance between the two components and therefore the weaker the force.

A Closer Look at Microfiber Cleaning Cloths

Tests have shown that microfiber cloths, which are either polyester or a polyester/polyamide blends, are more efficient than your standard cotton toweling for cleaning (Nilsen et al 2002). The reasons for their efficiency include a much higher surface area offered by the very fine, ridged fibers and static charge. Not only are soils “trapped” in between the ridges, but the fine filaments also provide strong capillary action, drawing in 8 to 25 times their weight in water. Also, polyester fiber is hydrophobic, lifting contaminants such as fingerprints off a glazing surface without the use of surfactants (Hartog and Porter 2017).

The Pros and Cons

Magnetic cleaning devices might make it easier to clean the inside of a display case that is difficult to access the inside. However, precautions must be taken, as the magnets in these devices could break the glass if the magnetic pull force is too strong; they could also affect some artifacts and should not be used near clocks, compasses, and electronics such as monitors displaying video art and other types of time-based media.

Other concerns involve the safety of the objects in the exhibit cases; there is risk of mechanical damage if the device falls. One thought is to cover the device in batting and fabric (to create a pillow of sorts) to buffer any potential contact.

As we continue to explore the potential use of these devices, we would love to hear from you. Adventures or misadventures using these devices or additional thoughts are most welcome.

References:

Hartog, F. and H. Porter. 2017. “The Powers of Microfibre Cloth,” Forum of the Institute of Conservation Textile Group, edited by Sarah Glenn and Katie Smith. Bath: ICON Textile Group. 41-48.

Nilsen, S.K., I. Dahl, O. Jorgensen, and T. Schneider. 2002. “Micro-fibre and Ultra-micro-fibre Cloths, Physical Characteristics, Cleaning Effect, Abrasion on Surfaces, Friction, and Wear Resistance,” Building and Environment 37: 1373-1378.

Poulin, J., H. Coxon, J.R. Anema, K. Helwig, and M. Corbeil. 2019. “Investigation on Fogging on Glass Display Cases at the Royal Ontario Museum,” Studies in Conservation 65 (1): 1-13.

Spicer, G. 2019. Magnetic Mounting Systems for Museums and Cultural Institutions. Delmar, NY: Spicer Art Books.

About The Author(s)

Gwen Spicer

Conservator in private practice

Yadin Larochette

Tru Vue Museum and Conservation Liaison for the Americas

Yadin Larochette is a Museum and Conservation Liaison for Tru Vue. As liaison, Yadin helps build and manage relationships with clients ranging from large distributors to small business owners, and with end users such as art conservators, preparators, curators, collections managers, and private collectors of art and historic documents. Serving as a consultant and technical point of contact for end users and channel partners, she helps clients address product application challenges.

She received a BA in Art History from the University of California at Berkeley and an MS from the Winterthur/University of Delaware Program in Art Conservation. A fifth generation French tapestry weaver, she wove professionally before embarking on a career in textile conservation. She is a Professional Associate of the American Institute for Conservation and ran a textile conservation private practice for 10 years prior to joining Tru Vue in 2015.